The packaging industry is undergoing a profound transformation. Smaller batch sizes, a wider range of materials, and growing sustainability demands are driving the need for innovative machine concepts. At the same time, cybersecurity and digital compliance are non-negotiable. Machine builders require solutions that evolve with these changing demands.

Lenze – your trusted partner for tailored packaging solutions. Leverage our concentrated expertise. With a scalable portfolio and open system architecture, we collaborate to develop high-performance packaging machines for consumer goods and pharmaceutical applications. Our motion control technology, backed by deep application know-how, helps you build packaging machines that are both precise and powerful.

Modular & flexible packaging machines

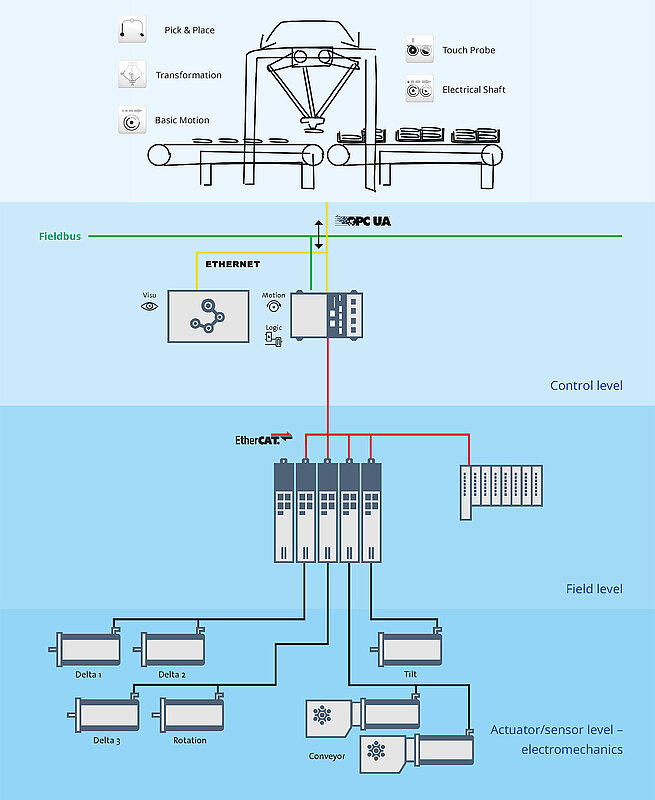

Small batch sizes, fast cycle times, diverse product lines, and customized packaging – the food industry demands maximum flexibility. Machine operators need energy-efficient packaging machines with precise motion control that reliably handle a wide range of sizes, shapes, and materials. With our comprehensive motion control portfolio, we take care of the complex tasks of motion control for you, giving you the freedom to design a modular machine architecture tailored to your needs.

Precise packaging systems

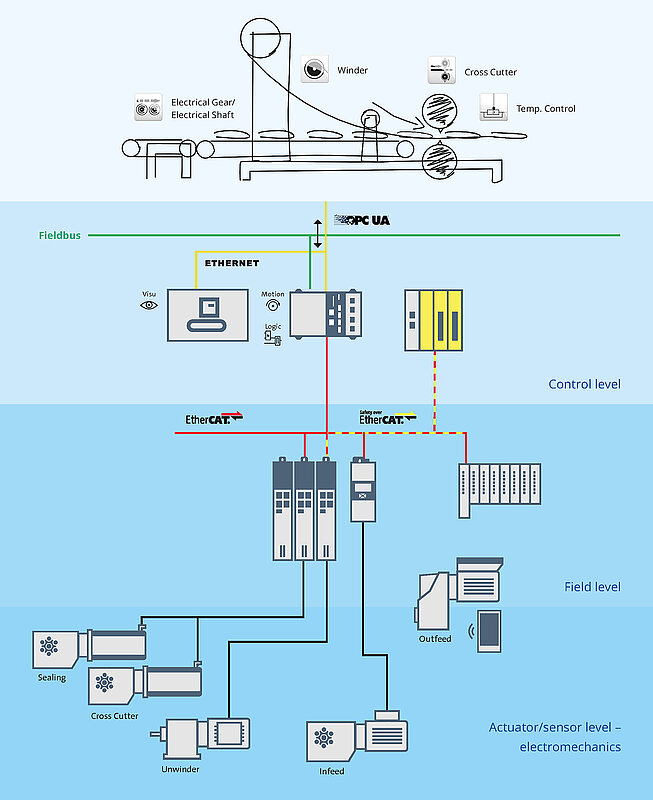

A wide variety of packaging materials – from films and cartons to delicate products – requires flexible and highly accurate motion control. Whether it's simple positioning or complex high-speed robotics, your packaging machines must be scalable and powerful.

Lenze supports you with a comprehensive motion control portfolio – from controllers and servo drives to gearmotors. With Lenze’s broad range of electromechanical solutions, you can build high-performance packaging machines tailored to your needs.

Sustainable drive and automation technology

The packaging industry is caught between cost efficiency and environmental responsibility. Machine builders must develop energy-efficient and resource-saving solutions – driven by regulations, rising energy costs, and growing sustainability awareness. Lenze supports the transition to recyclable packaging with energy-efficient technologies such as IE5/IE6 drive packages featuring sensorless positioning, regenerative drives, and precise temperature control for sensitive materials.

Your benefits at a glance:

-

Precise packaging thanks to end-to-end servo technology

-

Energy-efficient drive systems for sustainable processes

-

Easy integration into existing lines

-

Scalable machine concepts for future-proof production

-

Faster time-to-market thanks to Lenze FAST Software Engineering Modules