KABTEC builds test systems for Lenze's i500 frequency inverters

It's a special job for KABTEC the mechanical engineering company has developed the very technology needed to put devices or modules through their paces for Lenze's frequency inverters. In addition, the very inverters that are to be tested are also installed in the system. KABTEC from Bad Feilnbach in Bavaria was faced with this exciting task when it was commissioned to build test technology for Lenze's i500 series of inverters. "Lenze is both a customer and a supplier," is how Michael Vogtherr describes the unusual situation. The Head of System Projects at Lenze was involved with his team in the planning and realization of the test systems. These are located at Lenze's headquarters in Groß Berkel near Hamelin. Here, control assemblies undergo in-circuit tests and completely assembled devices end-of-line tests.

Reaching into the modular system

KABTEC was commissioned to build the appropriate systems for both test procedures. These were largely implemented using Lenze products. "We used inverters, safety components, PLC, HMI as well as motors and gearboxes," reports Florian Baumgartner, Head of Development at KABTEC.

The system aspect is enormously important for the special machine manufacturer from southern Germany because the solution space of coordinated components is correspondingly large. For Lenze, KABTEC in turn designed systems that are optimized for the needs of electronics production. "With the two test facilities, we can serve all product variants without retooling," explains Markus Hübsch, Head of Sales and Marketing at KABTEC.

Reliable and future-proof

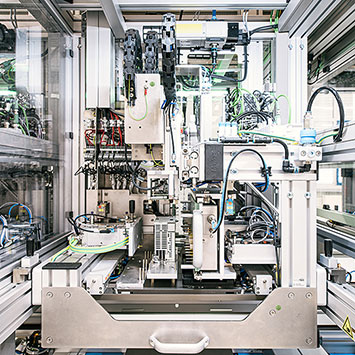

The Bavarian special machine builders kicked off with the in-circuit test system for testing assemblies based on KABTEC's already available KT500 series. The solution is essentially comparable to a contacting station, which is loaded with the test objects either manually or fully automatically. For this purpose, the system works with a gantry system with two PCB grippers.

Florian Baumgartner continues, "To achieve the necessary throughput, the single test station was duplicated." Contacting stations that are independent of each other and can be removed from the system, with quick-change contact cassettes that establish contact between the tester, machine and DUT, enable an almost undiminished throughput, even during maintenance work.

"In order to implement the exact requirements of such complex special

machines, commitment is required on all sides. A common understanding

of technical issues and procedures has developed in the projects."

Florian Baumgartner, Head of Development at KABTEC

"We had eye-to-eye communication with our colleagues from production and application. We communicate absolutely honestly and trustingly, even when it comes to the last technical bit & byte. And that is what distinguishes the cooperation and partnership with Lenze."

Markus Hübsch, Head of Sales and Marketing at KABTEC

Modularization of machine functions

The Lenze FAST application framework was used for efficient software engineering: "We are characterized by the fact that we specify software in a modular way. This is particularly suitable for special machine builders," explains Michael Vogtherr. These software modules include pre-configured motion functions, which in turn makes it easy to further develop the systems. "And we have exploited the advantage as far as possible here, because we can divide the systems into modules very well."