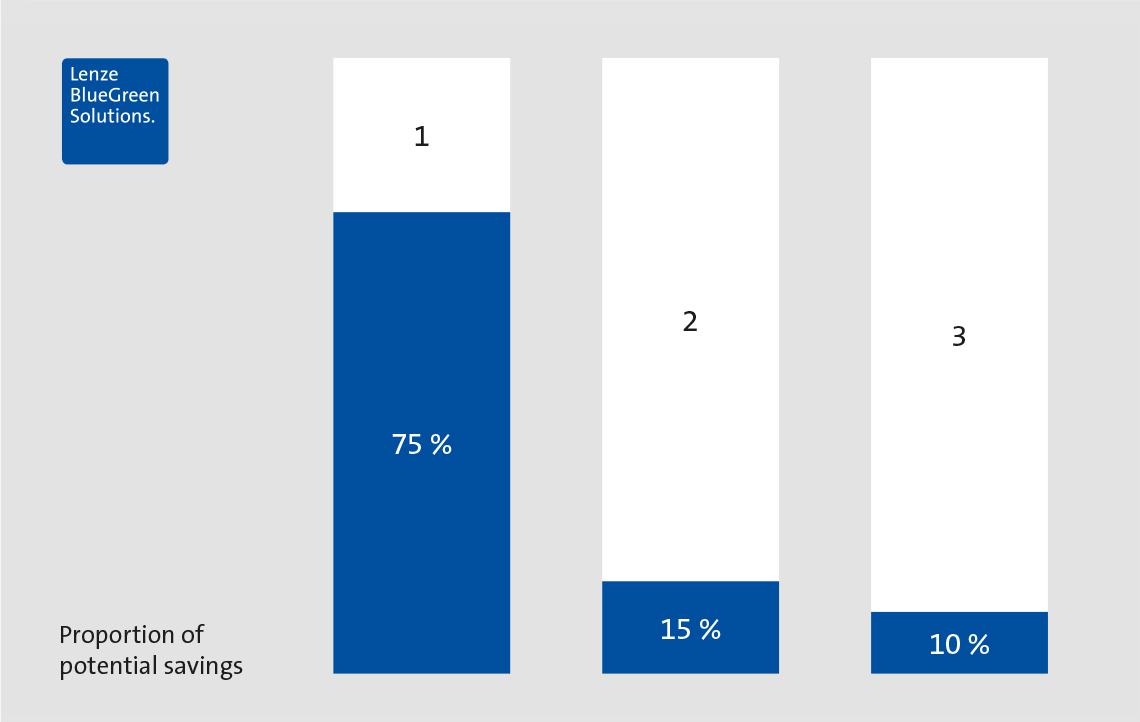

Three approaches are pursued in order to increase the energy efficiency of drives:

1. Using electrical energy intelligently: As little as possible

- Needs-based dimensioning

- Controlled operation (frequency inverter)

- Energy-efficient motion control

2. Converting energy with a high degree of efficiency

- Components with a high degree of efficiency (motors, gearboxes)

3. Using regenerative braking energy

- Energy exchange between several drives

- Temporary storage of braking energy

- Regeneration of braking energy and potential energy

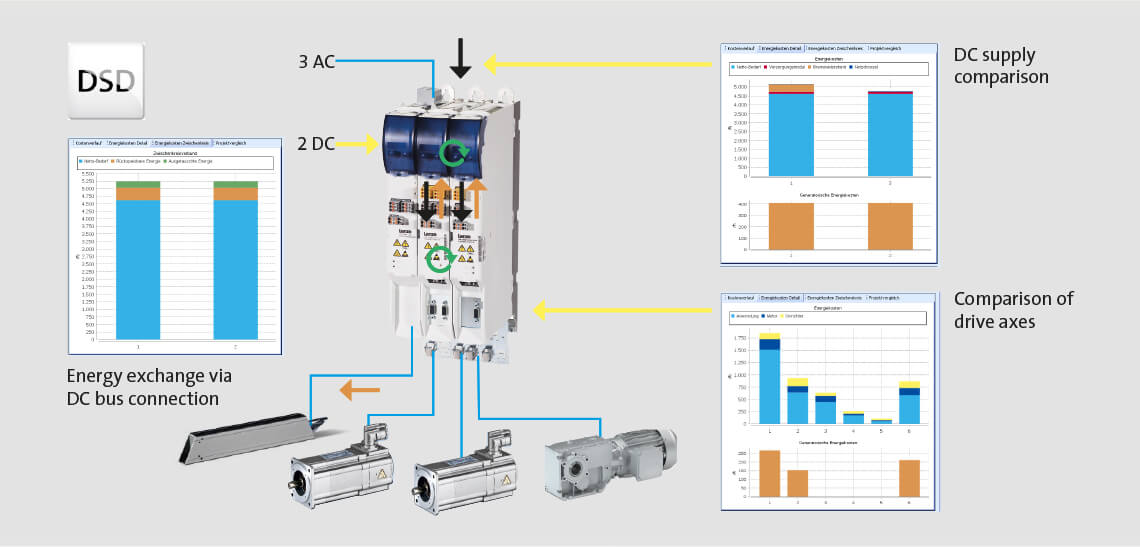

Efficient drive sizing with Drive Solution Designer (DSD)

Intelligent drive design is the basis for a drive system that has the right components, is exactly dimensioned and is therefore as small as possible. Thanks to Drive Solution Designer (DSD), the energy saving potential is apparent at a glance and is documented in the Energy Performance Certificate. It is also easy to comprehensibly compare different solutions.

The reason is that DSD incorporates a great deal of useful systems-design knowledge - with solidly based drive-applications know-how in areas such as drive physics, variants and energy efficiency. Drive design is based on calculations with individual process data and on speed profiles, and takes into account the complete drive structure for the requirements of the machine in question.

In our DSD training course, we will be happy to tell you more about how easy it is to use this engineering tool.