Intelligent solutions for smart production

Developed on the Mechatronic Competence Campus

Digitalization, sustainability, Industry 4.0 and ever shorter product life cycles challenge machine manufacturers every day to create future-proof machines for their customers.

Lenze understands these challenges and has aligned its working environment on the Mechatronic Competence Campus MCC accordingly. In Extertal, Germany various geared motor, servo motor and drive production sites have been combined. A customer-oriented, agile organizational matrix consisting of product management and production supports interdisciplinary work.

Such transparent processes and short paths facilitate the exchange of ideas between employees. New ideas, products and solutions for machine applications are created efficiently in order to master current and future challenges.

Experience technology every day – shape the future

This is what drives our employees: to continuously expand the mechatronic solution portfolio for our customers in international markets with efficient, high-performance, simply smart innovations and to strengthen their competitiveness.

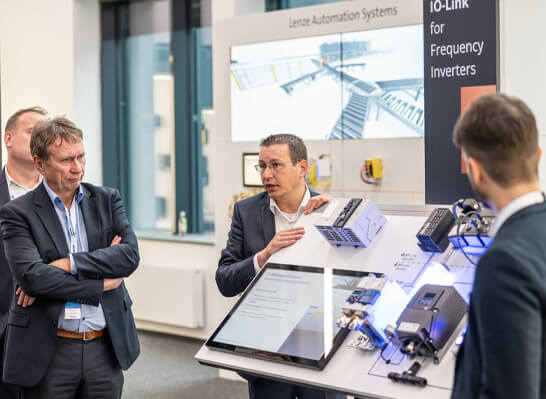

Technology you can touch, and so much more

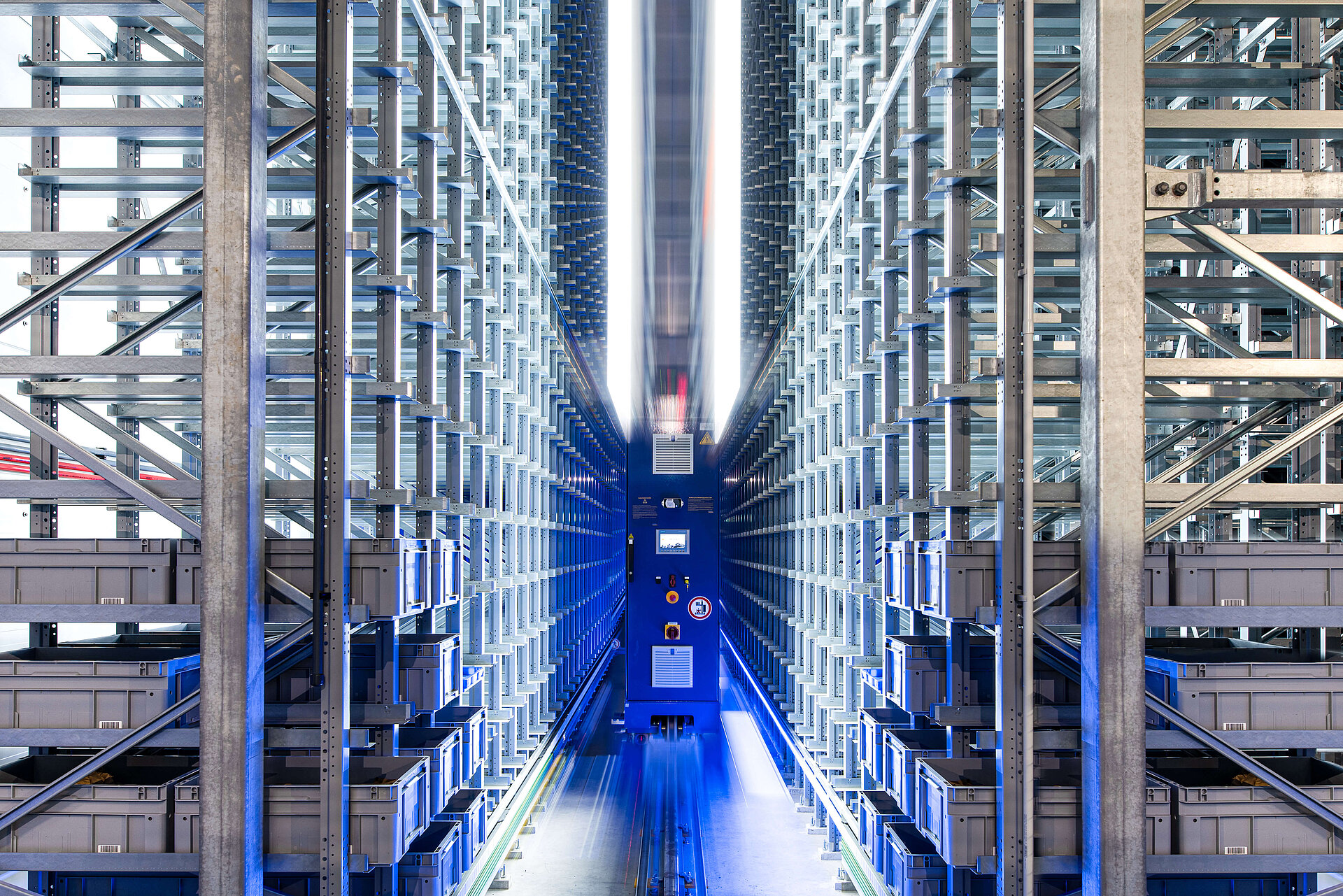

At first glance: Technology you can touch. At second glance, much more: a meeting point for workshops, external and internal training. Visitors get insights into production processes and a hands-on experience with Lenze products. Our high-bay warehouse focuses on the Smart Factory where engineering, energy-efficient products, digitalization and connectivity of machines and systems for sustainable production come to life.

At a glance – the Lenze portfolio

Get a comprehensive overview of the Lenze portfolio – from the drive shaft to the cloud. Experience how Lenze's electromechanical products work seamlessly together with Lenze control systems, controllers, HMIs, digital solutions and apps. This provides a sound basis to efficiently design machine applications and reliably ensure 24/7 operation with the help of smart data analytics.

Where innovation and product management meet

As a think tank, the MCC is closely connected with the international development teams in Switzerland and China. These teams stay up-to-date with the demand of the global markets and work with product development to design innovative solutions.

Some of these new solutions are incorporated into series production and continue to drive further product development. Notable projects include the Ide³AL project on innovative power electronics and the DC-Industrie research project which deals with the use of direct current from renewable energies in production.

Smart data optimizes Lenze logistics

Our new logistics complex comprises the following areas: Incoming goods, warehouse, production supply, dispatch and a 24m high-bay warehouse. We combine theory and practice in the high-bay warehouse! From the real-time data of our drives, we extract exactly the data that gives us information about the condition of the components and system. This enables us to reduce downtime, faults and rejects through condition monitoring and predictive maintenance. Valuable expertise to make processes safe and efficient worldwide.