Retrofit - This is always also a contribution to more sustainability

It's like a "fresh cell" treatment for the nonwovens line of the Saxon Textile Research Institute in Chemnitz. For more than 20 years, the production line has served well for research and development.

Now the time was ripe for a modernization of the application technology - and this in the form of a comprehensive retrofit, especially in terms of communication, sensor technology as well as drive and control technology.

Preserving the tried and tested, integrating the new

Operation - more intuitive. Spare parts availability - more reliable. Energy requirements - more efficient. Digitalization - with more possibilities. In the manufacturing industry, this four-pronged approach does not necessarily lead to the immediate purchase of a new machine. Nomaco GmbH, which specializes in nonwoven lines, sees itself as a know-how partner in precisely this area, in order to make aging lines fresh again for a second life cycle with an intelligent retrofit. "We are very strong in the modernization of textile machines - especially when it comes to electrical and control technology," emphasizes Managing Director Karsten Pelz. The company from Rehau (Upper Franconia) is very happy to take Lenze on board as a partner. "We map the entire system from the cloud down to the drives. This makes individual modernizations reliable and ultimately cost-effective," says Lenze sales engineer Axel Köller. The scope of services of numerous retrofits often also includes a modern, intuitively usable visualization as well as coherent concepts for remote maintenance. "Our customers don't want to worry about the drives or the control system - that's why total solutions are so important," emphasizes Karsten Pelz.

Lenze drives customized for individual customers

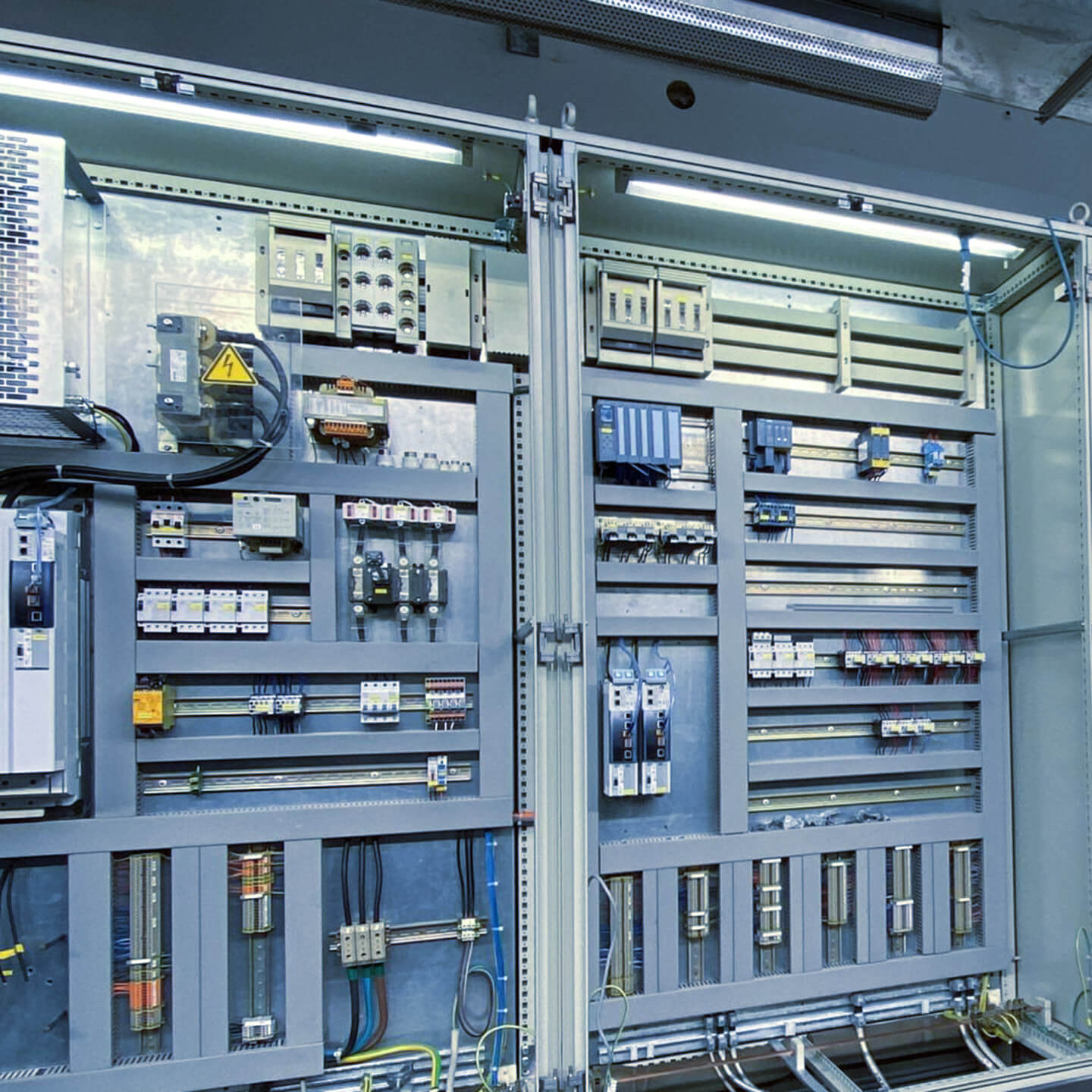

Filters, insulation material, disposable operating theatre clothing, geotextiles: nonwovens made of polyester fibres - so-called nonwovens - have a wide range of applications. An important location for application-oriented research: the Saxon Textile Research Institute (STFI) Chemnitz. In order for research to be carried out here under industrial conditions, state-of-the-art production technology is required. Instead of replacing an existing needlefelt plant, Nomaco was awarded the contract for a retrofit. And what applies to the factory also applies to the STFI: space is a scarce commodity, even when it comes to modernization. This statement may seem trivial, but it often makes a retrofit outside of limited budgets a real challenge - at the institute especially in the area of the control cabinets. The goal was to preserve these to a large extent. The inner workings, however, were new. Karsten Pelz: "In retrofitting, we want to preserve functioning processes - i.e. the mechanics. Modernize systems with a small budget and thus make them future-proof. We have been working with Lenze as a system partner for a very long time, also because of their know-how in the textile industry."

Duplicating know-how

To ensure that the retrofit at STFI was completed quickly, Nomaco divided the nonwoven line into functional modules and modernized them step by step. The modularization was also reflected in the software modules. "They are tested, can be adapted very well and, above all, can be reused in other projects," explains Axel Köller. "That makes such a retrofit reliable and fast." Another advantage: the machine modules remain fixed, even if the drive technology changes - for example due to varying outputs. In view of the increasing digitalization in machine and plant construction, Axel Köller sees further potential for improvement in the retrofit in the direction of digital services. This includes asset management as well as the analysis of machine data in the cloud or the broad field of condition monitoring.

Nomaco is now in a position to modernize old plants with Lenze's integrated automation system and to duplicate solutions and know-how in other projects. Open communication and integrated safety enable Nomaco to work independently of manufacturers, especially at the PLC level. "Here, too, we prefer Lenze," summarises Karsten Pelz.