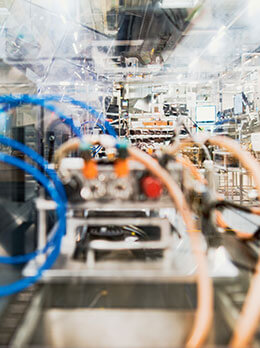

In the production of plastic components extrusion and injection molding processes are the key methods for producing very large quantities quickly and economically. At Lenze, we understand the dynamics of this industry and offer automation solutions that not only make production more efficient, but also integrate seamlessly with progressive automation and further processing steps.

Digitalization for greater efficiency

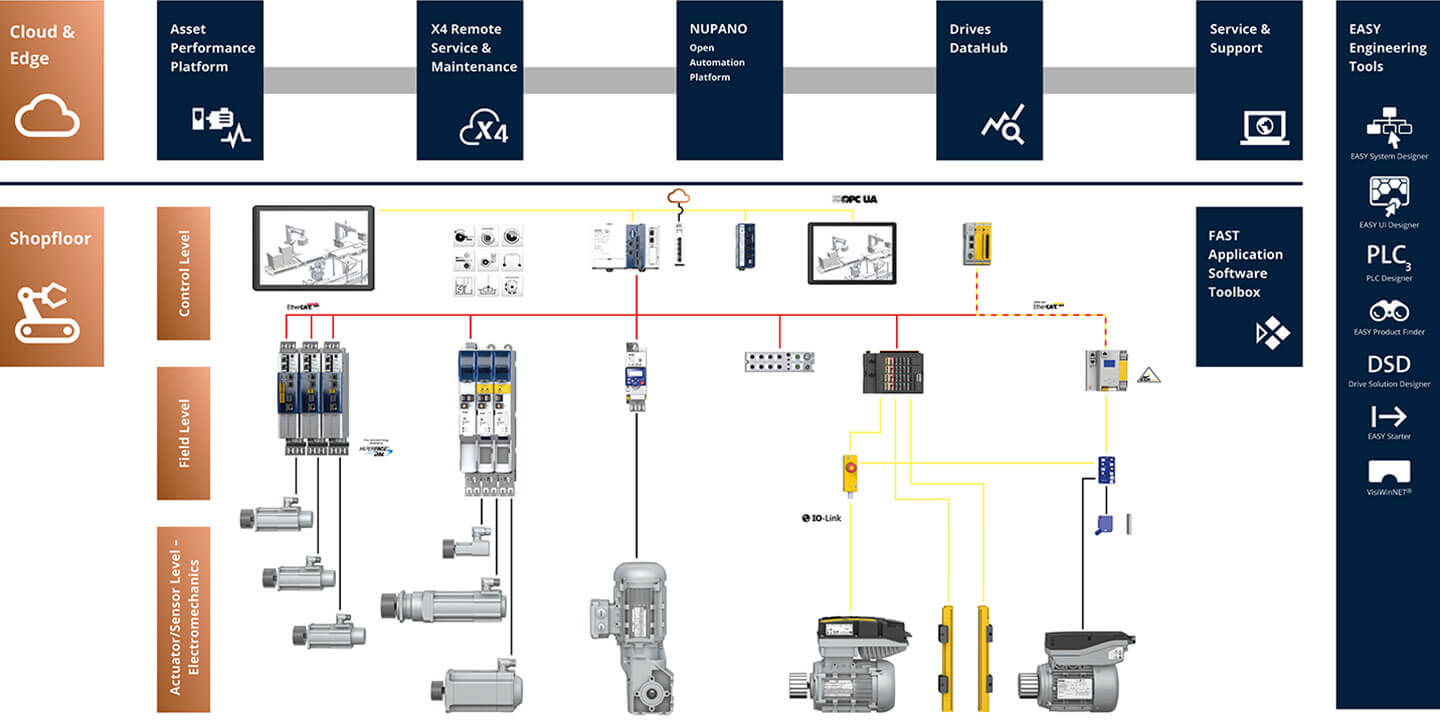

Extrusion and injection molding processes benefit significantly from the increasingly automated integration of subsequent parts removal and other processing steps. Here too, the aim is to use digitalization to make machines more efficient, faster and easier to operate. With our automation solutions, we offer the industry the right concepts and answers to support them in the digital transformation.

Optimization of the machine size

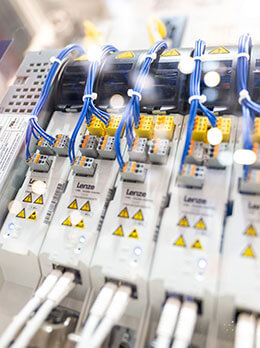

Our automation portfolio ensures the optimization of machine size by using suitably programmed servo drives i750 and i950 instead of mechanical or hydraulic solutions in order to make optimum use of space and resources. We therefore offer solutions that are perfectly tailored to the needs of plastic parts production.

Customizable visualization and operation

Our solutions offer easily customizable visualization and operation to maximize user-friendliness and provide operators with intuitive control.

Flexible parts removal with multi-axis kinematics

We solve the flexible parts removal with synchronized multi-axis movements to make production efficient and versatile. Use our i750 in combination with our powerful c520 controller and our Lenze FAST application framework for efficient software engineering.

Motion-synchronized processing with continuous extrusion operation

Lenze automation solutions are based on servo axes that enable motion-synchronous processing with continuous extrusion operation. Our i750 and i950 multi-axis servo inverters are our powerful answer to motion control applications, allowing you to benefit from maximum accuracy and higher throughput.