With its dosing systems for the perfume and flavor industry, Fricke Abfülltechnik is one of the market leaders worldwide. About one third of all flavors used worldwide are produced on Fricke systems. Because the company from Minden is internationally oriented, it turns the standardization screw with every new and further development. The central question is: Which components can best be used universally and how should assemblies be designed in order to solve many requirements with them? For drive engineering tasks, Fricke uses i700 servo controllers from Lenze - drive controllers that, due to their specifications, can be used worldwide and for almost all drive motors.

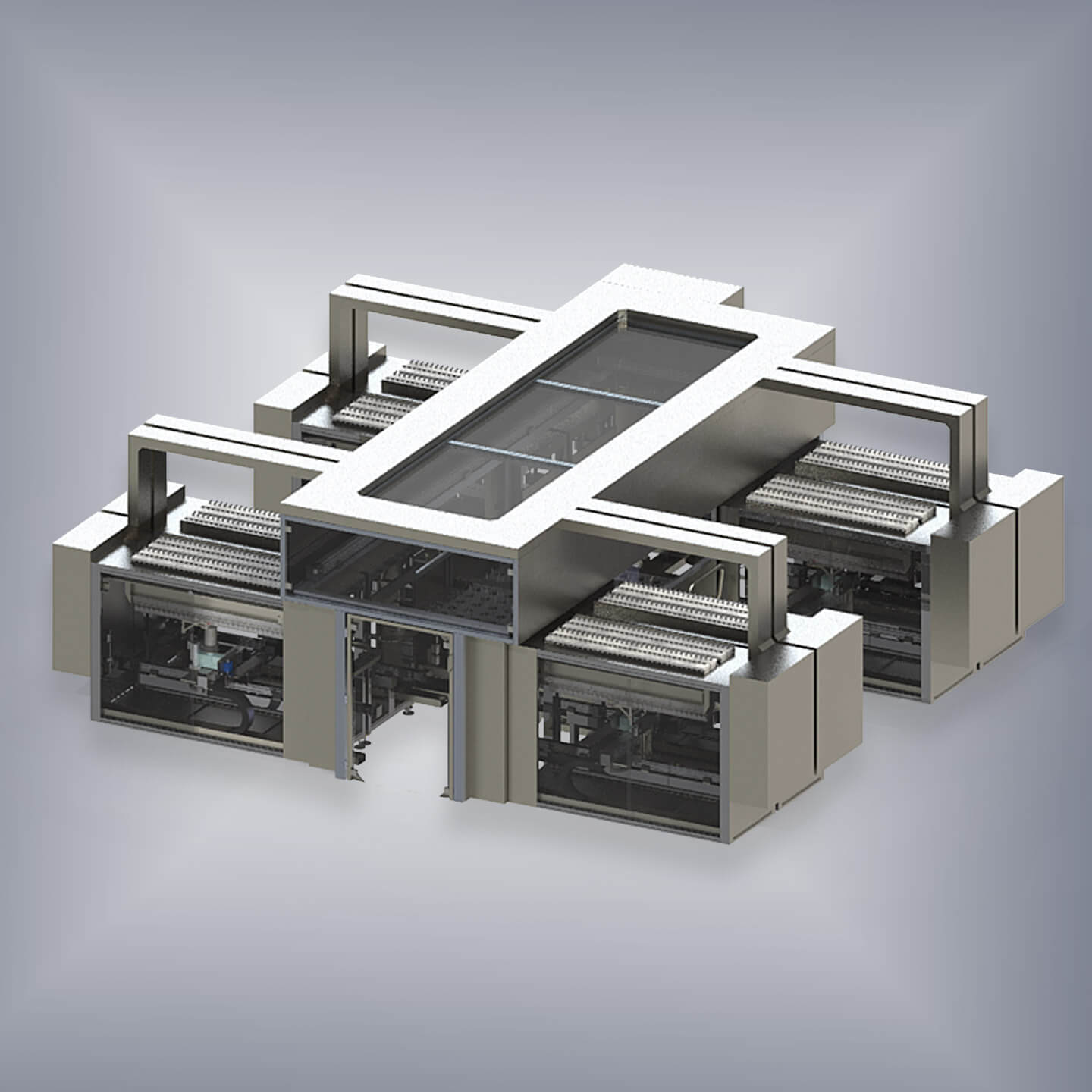

With the Dosingstar laboratory filling system, Fricke has developed a space-saving laboratory system which, in its maximum configuration with eight modules, automatically doses up to 800 components in batches with the highest precision. The accuracy for mixtures up to a volume of 1000 ml is within a tolerance window of ±3 mg. Fricke specifies the smallest dosing quantity as 5 mg - which corresponds to one tenth of an ordinary raindrop.

"If I can leave something out, that is of very high importance from the point of view of standardization and part variety. At the same time, we increase the stability of a machine because less can break. The genius is still in the simple."

Mario Markmann, Chief Technology Officer Fricke Abfülltechnik

In a Dosingstar, up to eight dosing modules, each with two servo-motor positioning units, are on the move. In addition, there are three axes working for the gantry system. This means that up to 19 axes are located under the roof of a central Lenze controller of type 3200C. With this central setup of 3200C controller, i700 servo controllers and ready-to-install linear axes with servo motors - often for hazardous areas - Lenze was able to offer a standardized drive solution as part of a joint engineering project.

By consistently networking the entire system with Ethernet and Ethercat for the drive technology, Fricke can very easily implement a central control architecture. In each module, further controllers control the processes, while the higher level takes care of which orders are to be mixed and in which sequence. In total, up to 10 controllers are installed in a Dosingstar. In view of the strong international orientation of the filling and dosing experts, the close interlocking of drive controller and servo controller makes it possible to exchange components without the need for specially trained technicians to jet around the globe.