Modern production systems are based on comprehensive networking and an extensive exchange of important useful data between production and management. At the same time, more networked machines mean more complexity - and thus higher demands on processes and technologies. Knowledge of the merging of the IT and OT worlds has become a precondition for success.

Sales

- Telephone

- +86 21 3828 0200

- info.cn@Lenze.com

Central use cases in industry

- OEE optimization capabilities with historical databases and dashboards - both on-site and in cloud environments

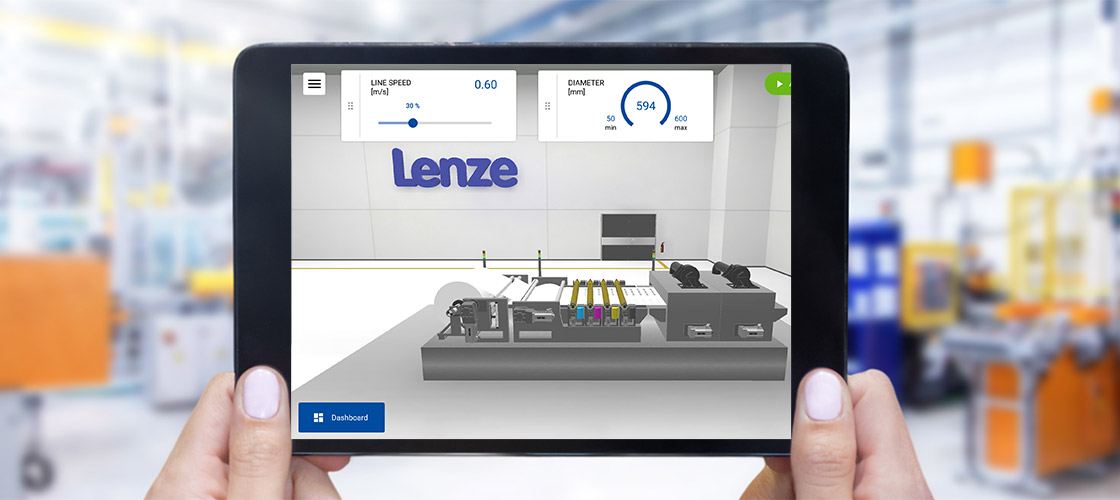

- Virtual Commissioning and 3D machine simulation to simplify and parallelize engineering processes

- Condition Monitoring of machines and plants with local data storage and aggregated data forwarding to the cloud

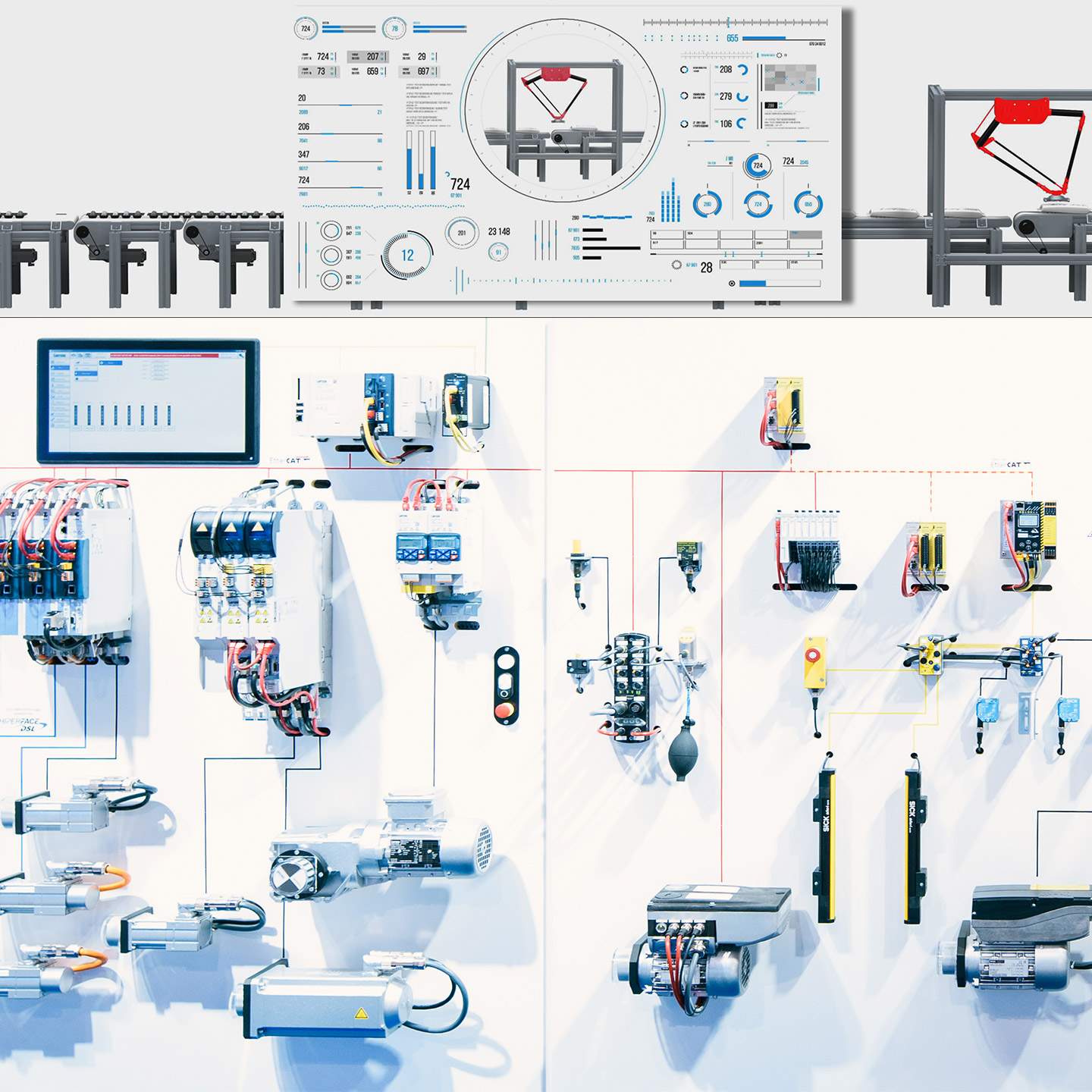

Our automation system offers you everything from the control level to the electromechanics for the implementation of a wide variety of tasks.

Benefit from reliable technologies, intuitive engineering tools and our open system environment. Our solutions are open for the efficient integration of 3rd party components and the integration into higher-level line topologies.

We offer application and engineering services for machine integration of Condition Monitoring, machine performance or virtual commissioning during the engineering process.

To enable machines in a smart factory to be integrated into the cloud, we supply IoT gateways and the cloud-based X4 platform for web services. This enables the simple and secure connection of Lenze's new generation of controllers to web services. And that allows you to keep an eye on machine data and statuses from any web-enabled device.