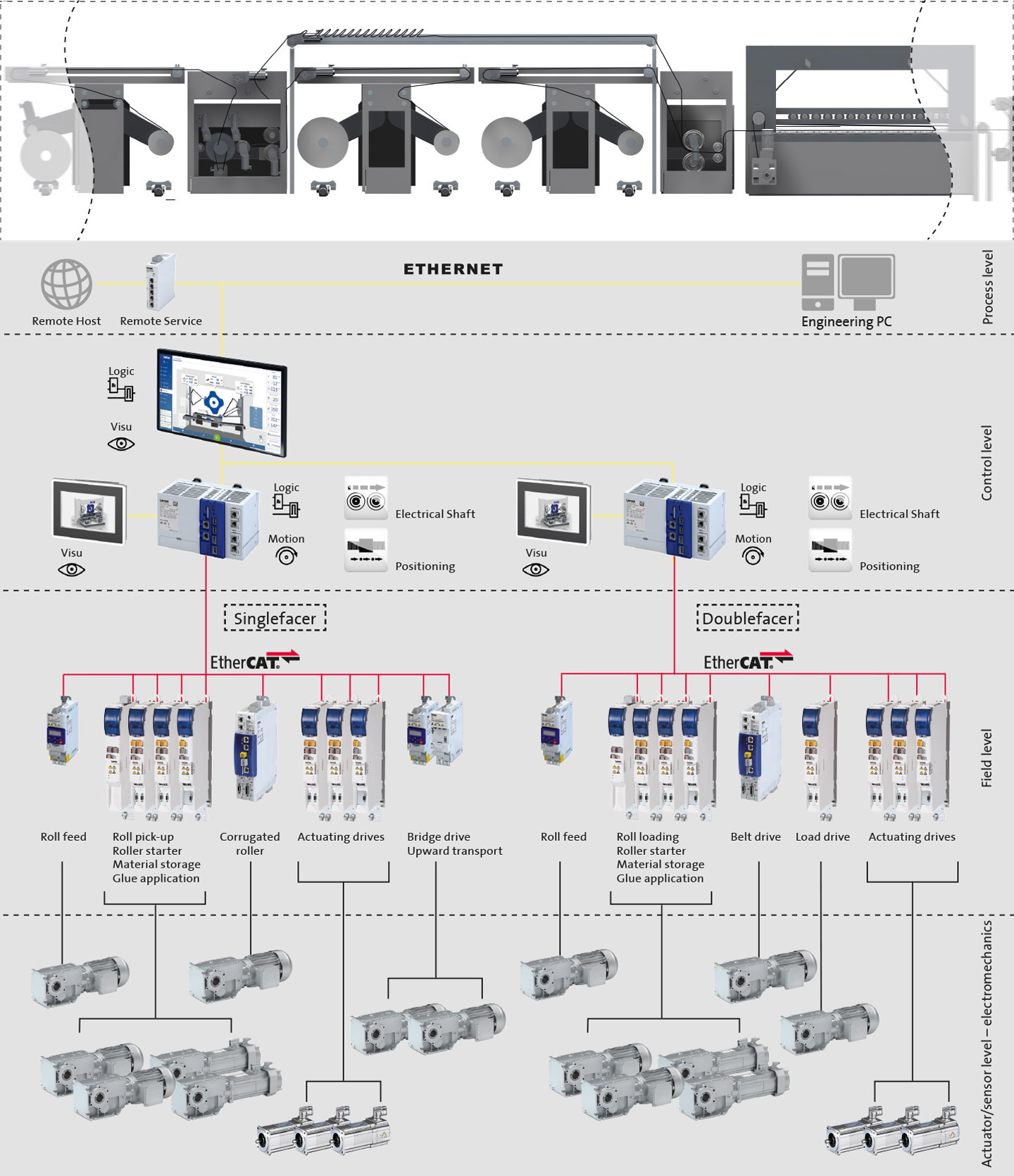

- Modular design of single-facers and double-facers with paper feeders under the control of one controller per machine module - with an interface to the overall plant control system. Very easy adaptation to the individual plant configuration is possible with regard to types of corrugation and corrugation combinations

- Universally usable drives, whose parameters are kept centrally in the higher-level control system and are transferred to the drives during initialisation. This enables lower stocks and easy servicing

- Energy-efficient operation thanks to DC-bus connection of track and brake assemblies, carriage units and roller starter

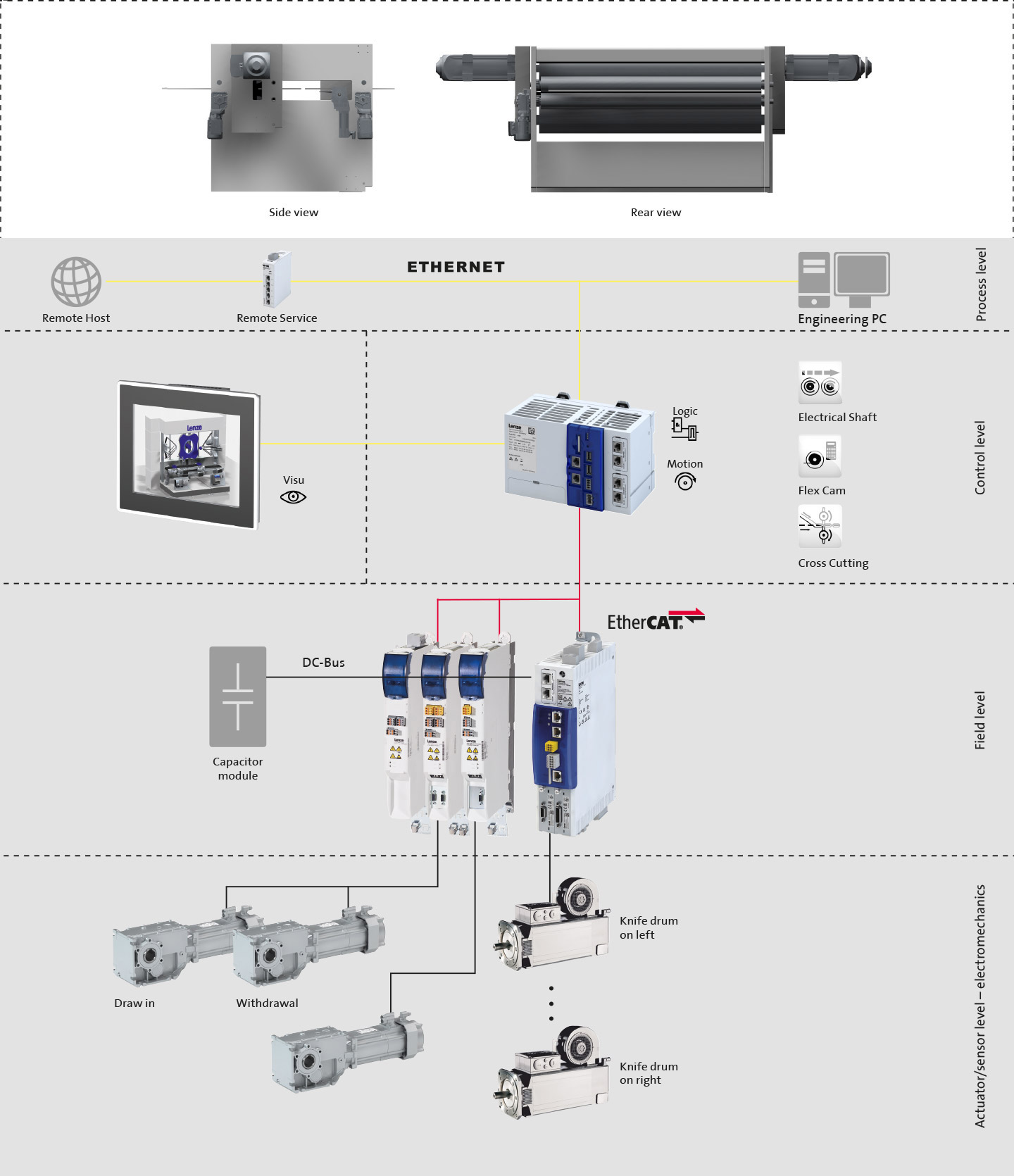

- Software engineering made easy thanks to Lenze FAST standard software module "cross-cutting":

- Scalable functionality and performance, from standard cross-cutting to highly dynamic operation with torque precontrol and precise cutting-mark synchronisation

- Integrated manual operation and referencing as well as visualisation

- Low supply power due to possibility of connecting an external capacity module for the dissipation and absorption of energy during acceleration and deceleration of the knife drum

- Energy balance between feed and output drives due to DC bus connection

- Low investment costs due to optional creation of a duplex cross-cutting system connected to a shared Lenze controller

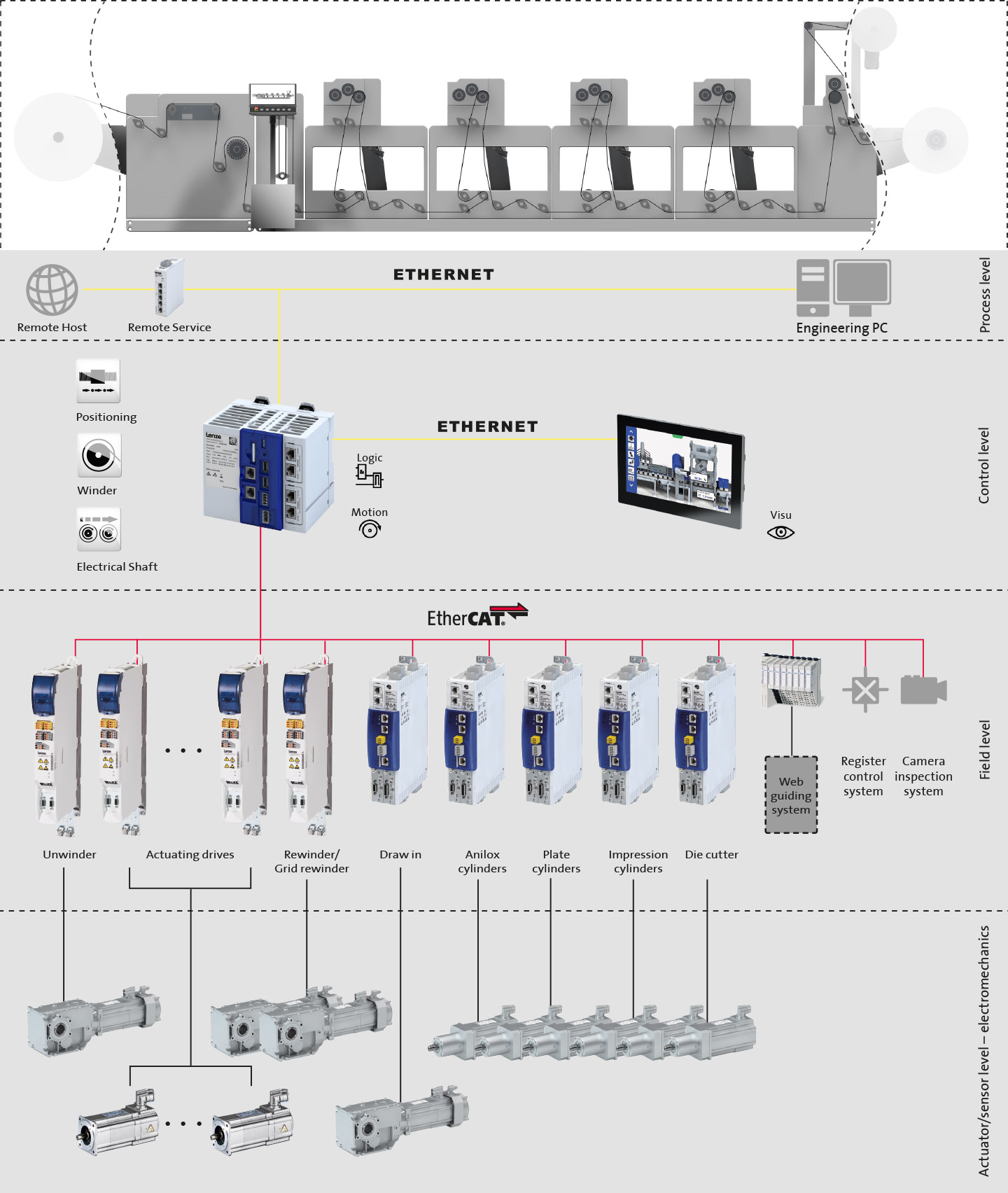

- Fast synchronisation of printing units via an independent CAN system bus for highly precise printing results

- Easy expansion due to the modular design of the printing units. The use of intelligent drives on the main line section enables additional colours and finishing stations without any notable extra stress on the higher-level machine control system

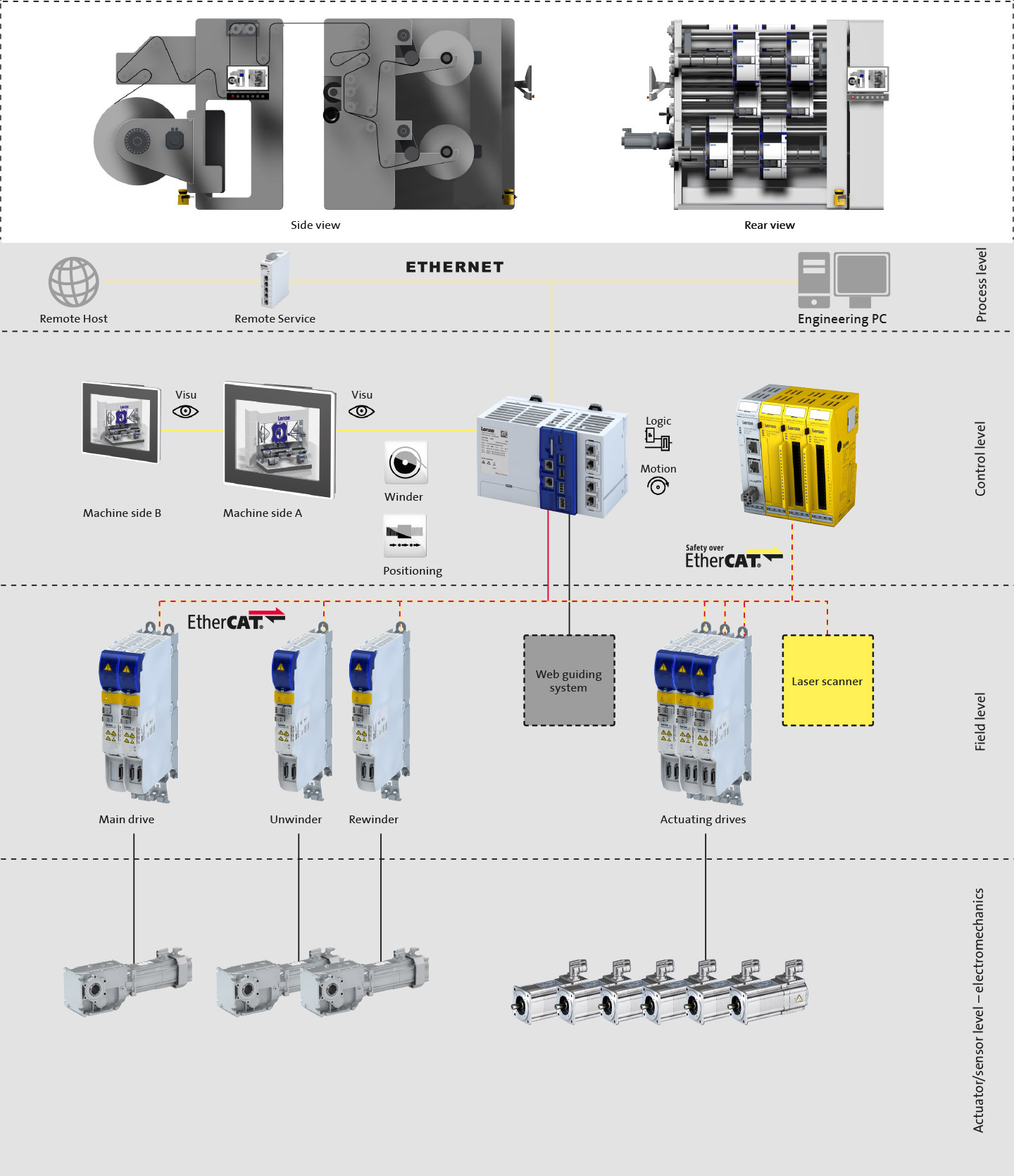

- Uniform development environment enabling easy integration of external actuators and sensors such as web guiding systems, register sensors and camera inspection systems

- Easy engineering due to uniform software environment for visualisation, printing roller drives and actuating drives

- Support of modular machine concepts based on a configuration for a maximum number of colours with optional nodes

- High printing precision due to synchronised servo axes

- High plant availability due to possibility of using an alternative printing axis in the event of a printing machine fault or failure

- Seamless automated from motion to logics and visualisation

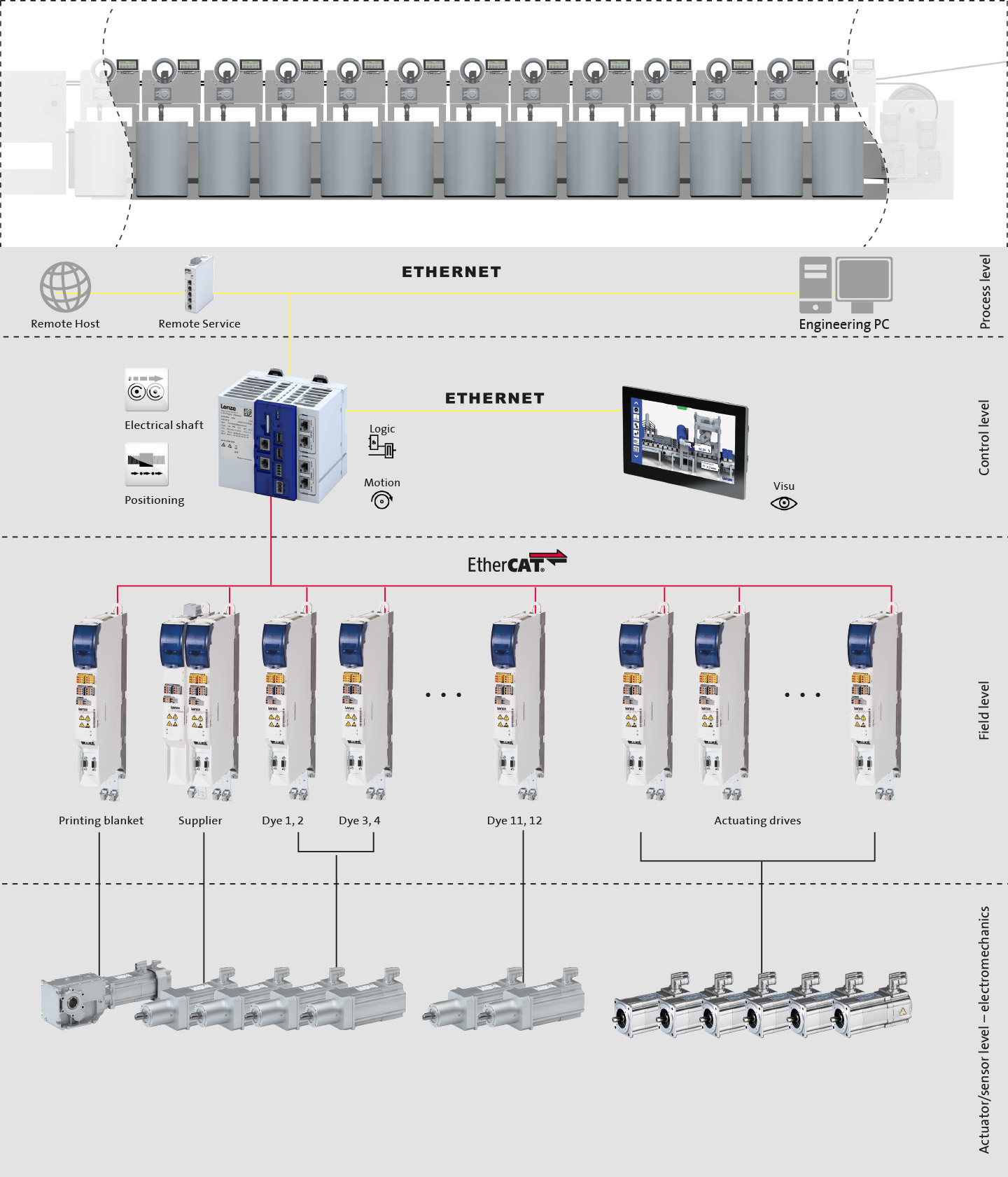

- The Lenze FAST standard software module "Winder" reduces costs and improves productivity and quality:

- Based on 70 years of experience in the field of winding

- Reduced winding drive power by full usage of the field weakening range

- Integrated torque and diameter calculator for reduced expenses on sensor technology

- High winding quality thanks to disturbance compensation (friction, acceleration)

- Easy operating mode changeover with assignment of product-specific winding characteristics for fast product changes

- Less wiring efforts due to pioneering EtherCAT/FSoE topology