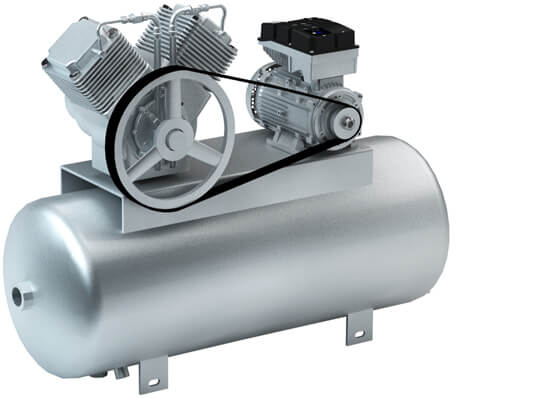

The majority of these compressors are operated with an on/off switch without speed control. The demand for more precise processes in production, along with the wish for greater sustainability, have led to more and more systems being controlled by inverters with both asynchronous and synchronous motors.

Motor- or wall-mounted

The variable speed control of the compressor is carried out via motor-mounted i550 motec – or alternatively for wall mounting.

The integrated IO-Link interface capability (IO-Link sensors can be read directly), the plug-in capability and the easy interaction via smartphone (RFID/WLAN) or USB make its handling much easier.

Lenze frequency inverters provide

Highest energy efficiency

| Robust design

|

More economical design

| Optional fieldbus interfaces

|

IIoT-ready

| Optimized for workshops with

|

Integrated EMC filter

| World's first IO-Link solution

|

Cost-effective

|