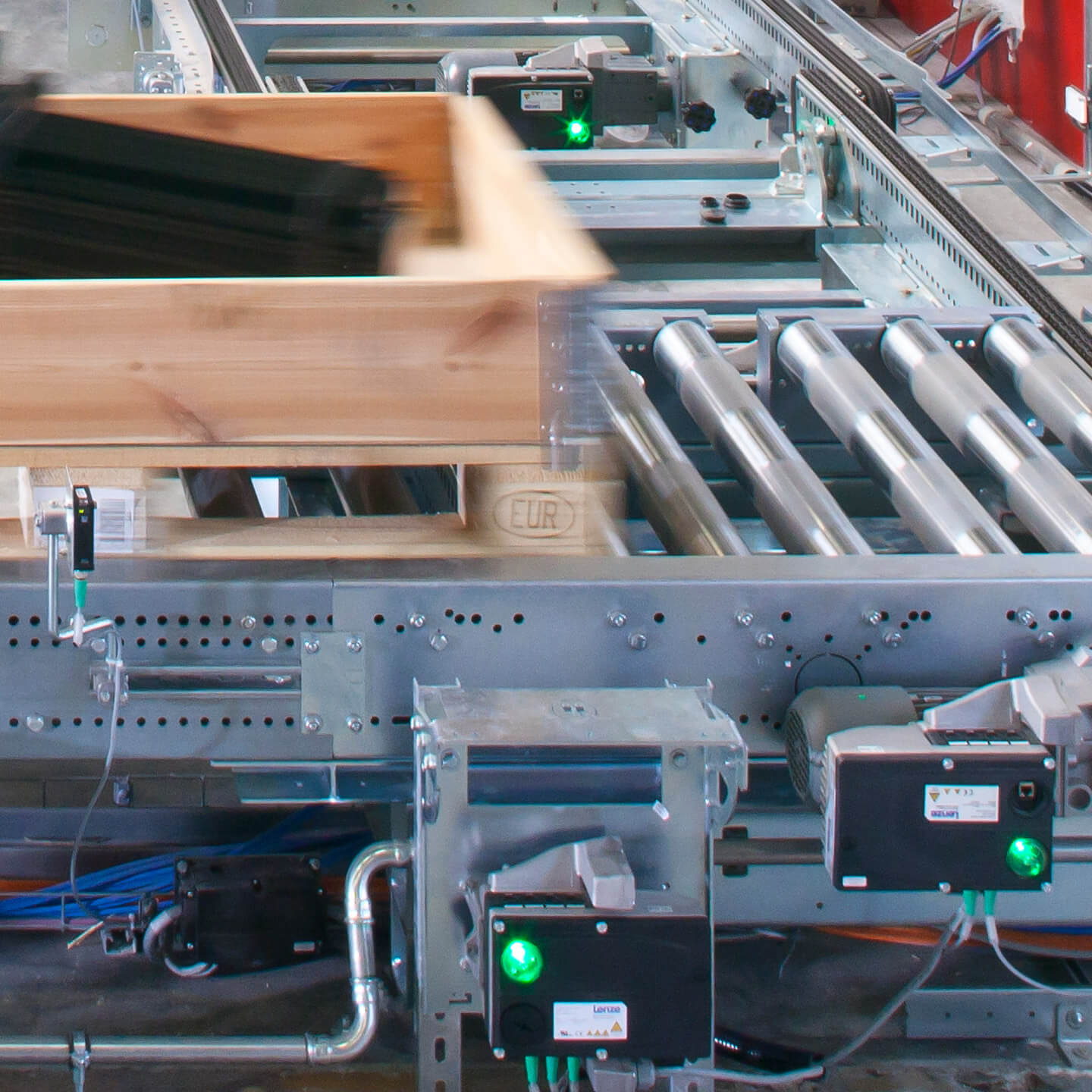

How the switch to a decentralized drive solution pays off

With a compact, scalable and efficient solution:

- Reduced energy consumption due to savings during idling and partial-load operation as well as due to use of the "VFC eco" energy saving function

- Compact drive solution, even in the case of heavy load

- Significantly smaller control cabinets and simplified topology

- A significant reduction in cabling costs

- A significant reduction in the number of drive versions

- Soft starting and braking with adjustable ramps mean less strain and stress on material and goods being transported, while simultaneously reducing the amount and cost of maintenance work needed

A numerical example for a materials handling application: With only six drives, a saving of 4,500 € in project costs and a further annual reduction in maintenance costs of almost 1,000 € could be achieved.

More about the 8400 motec decentralized inverter

A single motor for many applications in horizontal conveyor technology.

The Lenze Smart Motor – Contactor and starter do not feature, fixed speeds can be set at will and there are numerous integrated functions for materials handling applications:

- The functionality of contactor, starter and FI are covered in one device

- Up to 4 times overload reduces the variety of variants Speed, motor protection, control – benefit from fast installation and wiring options

- Freely adjustable conveyor speeds reduce risks in the project and minimise commissioning costs

- There is no brake wear – the Lenze Smart Motor has integrated brakes, eliminating the working brake protects the mechanics and the material being conveyed

- An integrated EcoMode saves costs for electricity and during commissioning and system operation

More about the Lenze Smart Motor

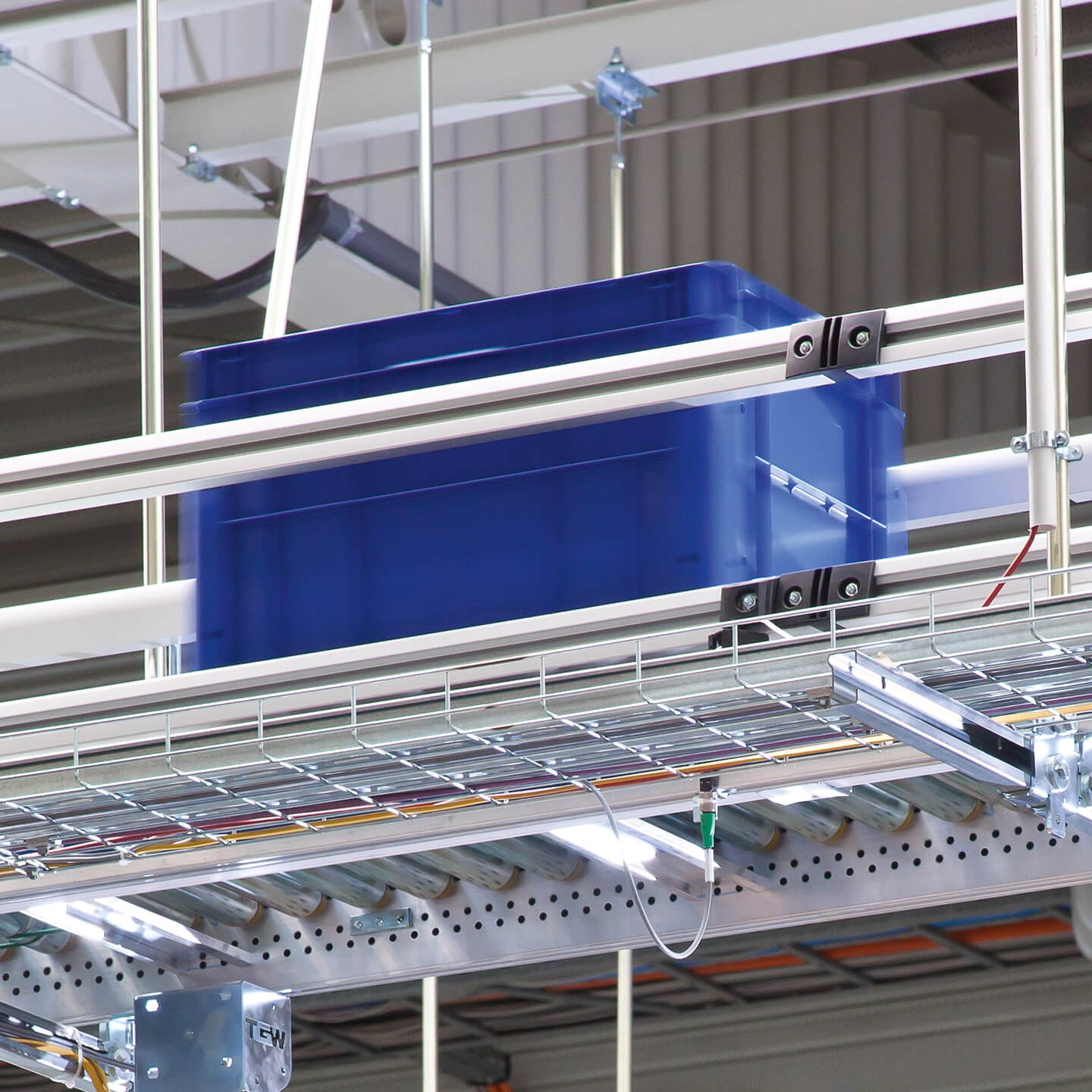

Precisely fitting for container conveyor technology

The Lenze Smart g350-B geared motor – Rely on the advantages of a standardized and tested solution for conveyed goods from 20 kg to 350 kg that can be used universally anywhere in the world:

- Simple modification of the mechanical connection on site reduces thee number of drive versions

- Reduced number of drive versions thanks to optimum oil

(wide temperature range (-30 - + 40°C) and food-compatible lubricant) - Freely adjustable speed reduces variety of variants

- Integrated soft start functionality

- Reduced wiring due to electronic contactor and motor protection function

- Outstanding energy efficiency

- Operation with an NFC-enabled smartphone and Lenze App

- Maintenance and wear-free for improved plant availability

More about the Smart Geared Motor