Industrial one-off production with series character

Anyone buying a new kitchen has a free choice: Surfaces, depths, heights, fittings, sink on the left - or rather on the right. Because grid dimensions are also becoming increasingly finer, more and more individually cut to size kitchens are being made today instead of standard kitchens. "Batch size 1 is still a hot topic," is how Schelling Marketing Manager Thomas Gsellmann sums it up.

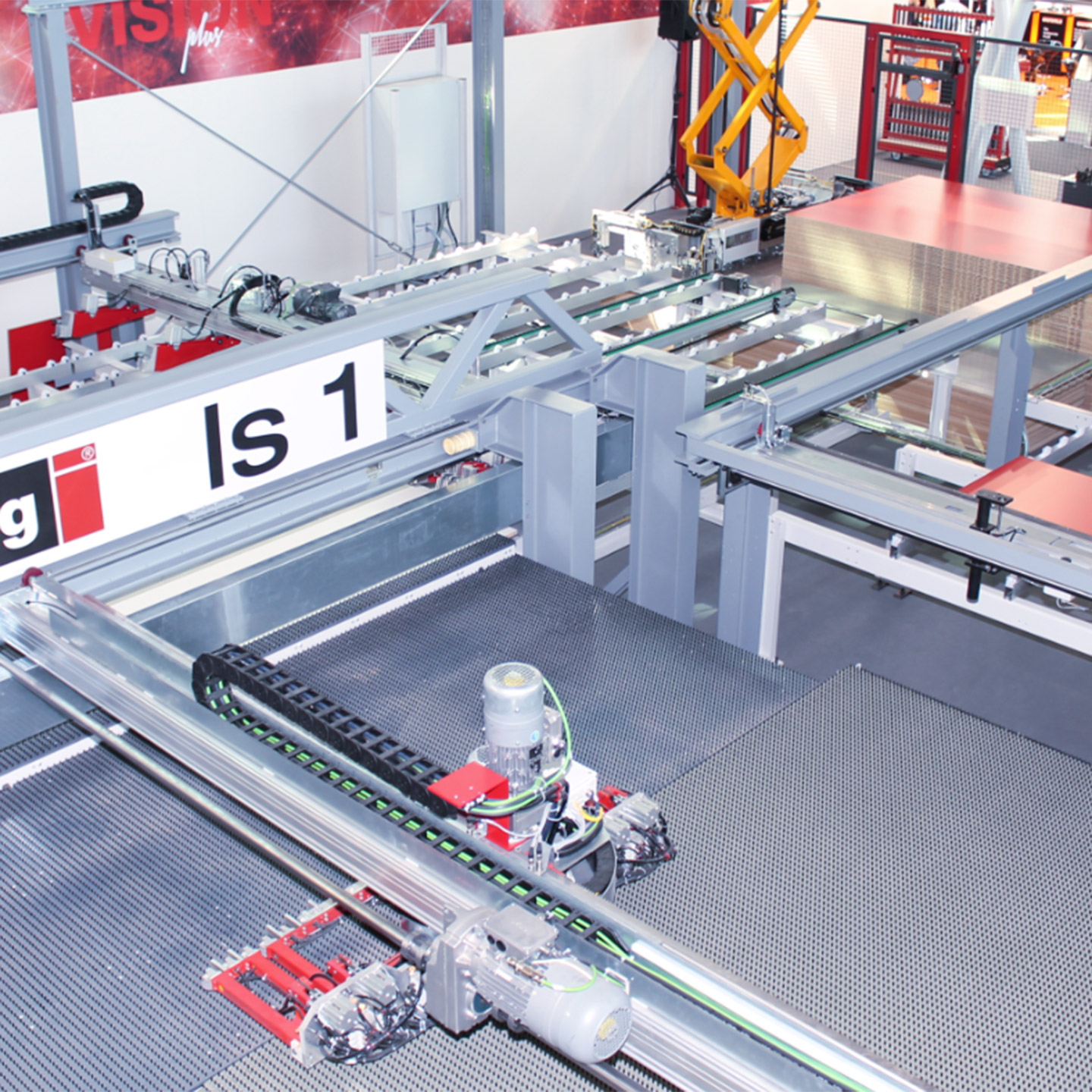

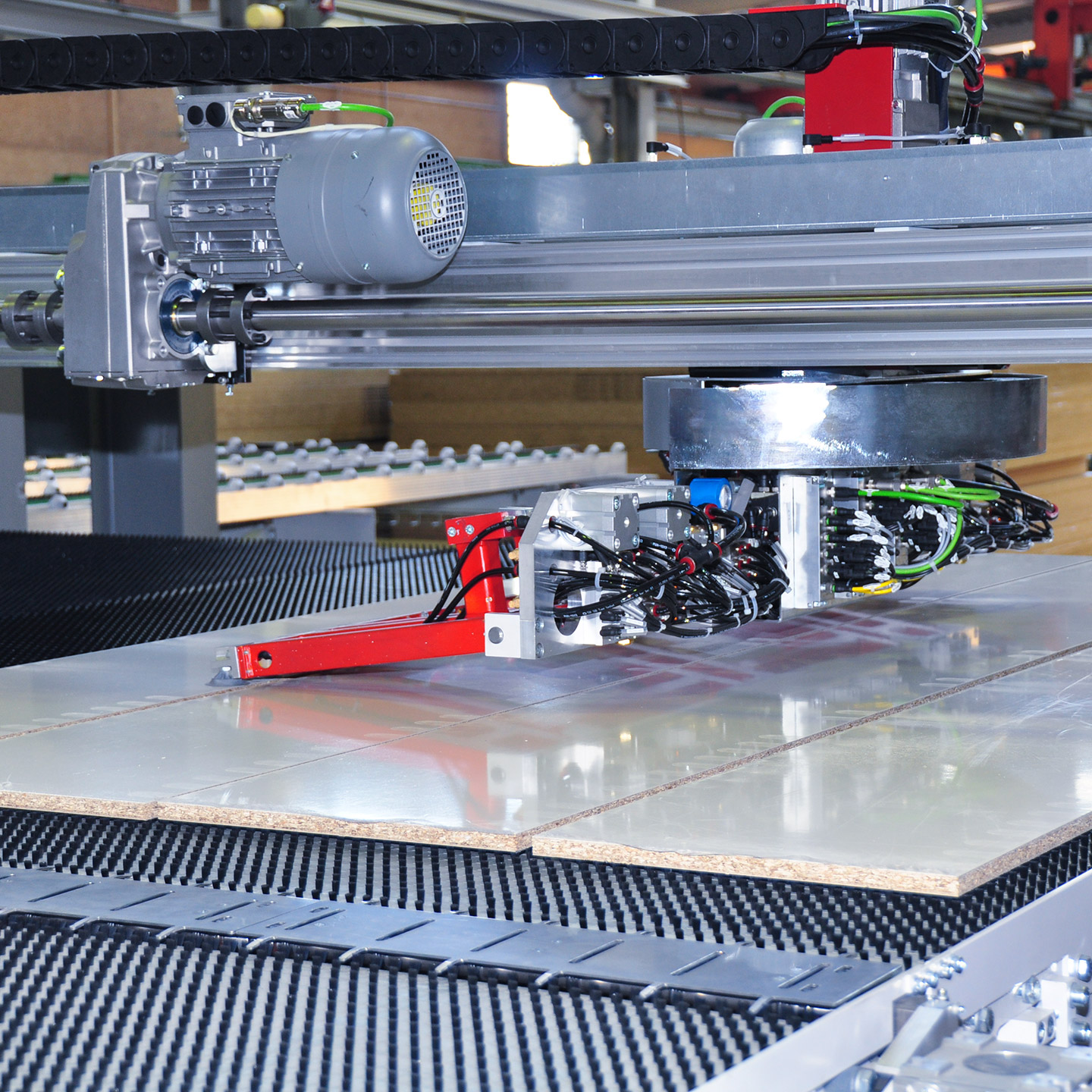

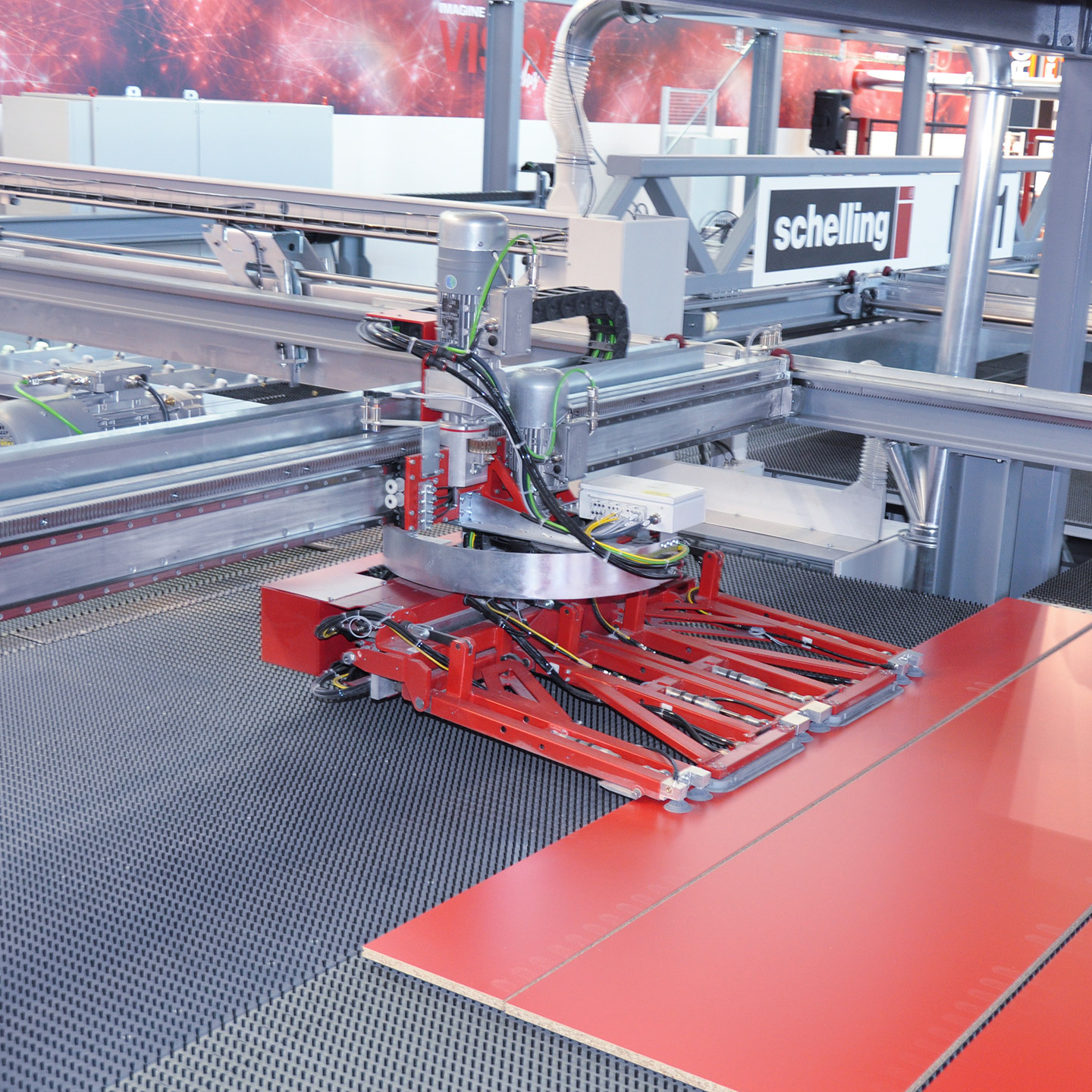

The sawing center from Schelling shows how such a solution can look in practice. Thanks to a circulating materials handling system with two gantry units, the "Is1" sawing line can operate without interruption. The so-called manipulators were developed in a close technology partnership with Lenze. The heart of the motion control solution is the Lenze FAST technology module "Pick & Place" for robot applications.

Individualized plate partitioning

Where every kitchen wants to be manufactured according to the end customer's personal specifications, mass production and batch processing are a thing of the past. The digitized kitchen plans are translated into parts lists and cutting plans. Each part is sawn individually yet fully automated by the Schelling "Is1". "The saw is integrated into a higher-level control system, whereby it is the clocking element in the production line," says Dietmar Nußbaumer, Head of Technical Systems and Installation at Schelling, describing the requirements profile for this machine solution.

"We are increasingly thinking in terms of mechatronic machine modules consisting of mechanics, electronics and software that we can reuse for other projects.

That's why we need full-service providers who also support us in software development."

Dietmar Nußbaumer, Head of Technical Systems and Installation at Schelling

Robotic functions in the gantry

The core principle of the circulating materials handling system is based on gantries that rotate the panels after the first longitudinal or head cut and transport them on to the next saw cut via brush tables that serve as buffers - in principle, the rotary concept allows cutting plans to be optimized in several planes. Once the parts are finished, a gantry discharges them again for further processing. When designing the gantries, Schelling and Lenze used FAST technology. This is a fully-fledged robotics core that offers everything machine builders need for fast and flexible handling tasks, even without special knowledge of robotics.

The advantages: Time savings and cost savings because a deeper dive into motion control programming is not necessary, improved software quality through structured programming, and easy reuse. Since specific functions can also be easily integrated, the "Pick & Place" technology module can be easily adapted to the special features of an application.