Intralogistics solutions in warehouses, airports or distribution centers benefit from the endless opportunities that our new motor driven roller offers for your conveyor design.

The active gearless MDR is suitable for a wide range of applications in your conveyor systems.

- Up to 2x as powerful as other MDRs thanks to the innovative motor design

- 15 % energy saving compared to conventional MDR, comparable to efficiency classes IE7 to IE9

- Quiet operation with design based on Vernier-principal

- Minimal variance: One covering all speed and torques

- Voltage flexibility: Single variant can run on 24 and 48 VDC

![]()

Flyer: Motor driven roller o450

Data: Motor driven roller o450

The new MDR enables significantly faster goods transport – twice as powerful as conventional motorized castors thanks to the unique, brushless motor concept.

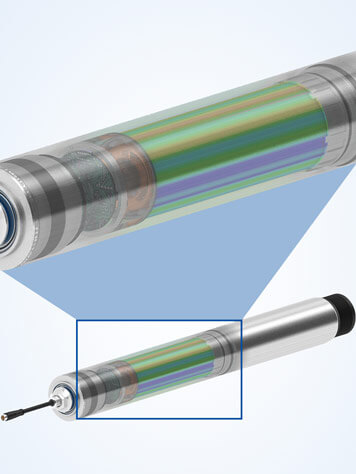

The innovative motor design works according to the Vernier principle: a magnetic gear effect is generated, which makes the o450 motor driven roller powerful and efficient. The power electronics are integrated inside, and the roller is extremely compact with a diameter of 50 mm.

Our MDR is gearless, which saves on variants. This makes many processes less complex, such as purchasing and design, and maximizes flexibility in operation and maintenance.

With fewer stock items, you are much more flexible and can solve the many different applications in loads and speeds that are common in intralogistics. You can cover a wide range of solutions with fewer components. Universally deployable are 24 V (57 W) or 48 V (110 W). And did we mention that the new MDR can be easily integrated into many systems?

Cost and energy savings are the result of the compact and gearless design. Friction losses are completely eliminated. The efficiency of the MDR is 15% higher than that of conventional motor rollers with gears.

We are also proud of the fact that the motor design not only uses less active material but is based on a newly developed magnet type that uses 30% less rare earth than conventional magnets. This in total means >50% less rare earth material used.

The new MDR in 24 V / 48 V is a real pacemaker for your application and silently accelerates with 5 Nm peak up to 1.5 m/s and with a nominal torque of 1.35 Nm. The innovative permanent magnet motor represents a new drive concept. Use it to successfully design accumulating conveyors, roller conveyors, and other dynamic conveyors.

Vernier principle:

Creates a magnetic gear effect

Accumulating roller conveyors and roller conveyors

Smooth operation

Horizontal transportation of full and empty crates, cartons or highly sensitive goods in polybags suits the Lenze motorized roller. How you use the o450 is entirely up to you. We guarantee smooth conveying. The roller also reliably drives belt conveyors.

Cross conveyor

Fast change of direction

When it doesn't just run in one direction, but in all possible directions. Running in one direction, but also arriving sideways – this is one of the applications for which the o450 MDR is predestined. Many sideways movements and industrial applications are reliably implemented in this way. Peak torques of up to 5Nm are possible.